We are Consultants to the Metals Processing industry.

|

2006 Successfully Completed Project: For SMS-Demag AG (Germany) at Jigang Steel, Jinan, China Continuous Pickling Line

|

|||||||||||||||||||||||||||||||||||||

|

Line Specification:

|

|||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

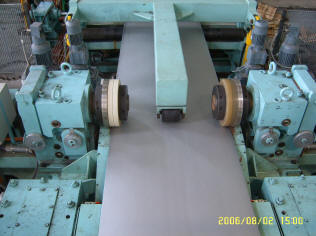

Steering unit for Exit Strip Accumulator / Notcher and Side Trimmer steering |

|||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||

|

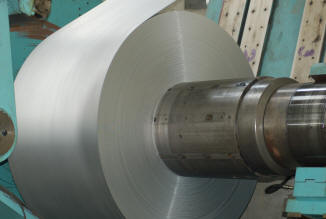

Side Trimming |

|||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

Johannes, Franz, Chris, Peter, Martin, Thomas and Volker |

|||||||||||||||||||||||||||||||||||||